Commercial roofs across Los Angeles carry a unique workload. From small storefronts in Highland Park to sprawling production facilities in the Valley and creative office conversions in the Arts District, these buildings often combine low-slope assemblies, rooftop equipment, and strict energy standards. When managers and owners ask how commercial roof replacement plays out in our city, the answer begins with building usage and expands to codes, logistics, and life-cycle strategies. If you’re framing plans for a commercial roof replacement, this overview will help you align expectations with the realities of the LA market and the demands of your property.

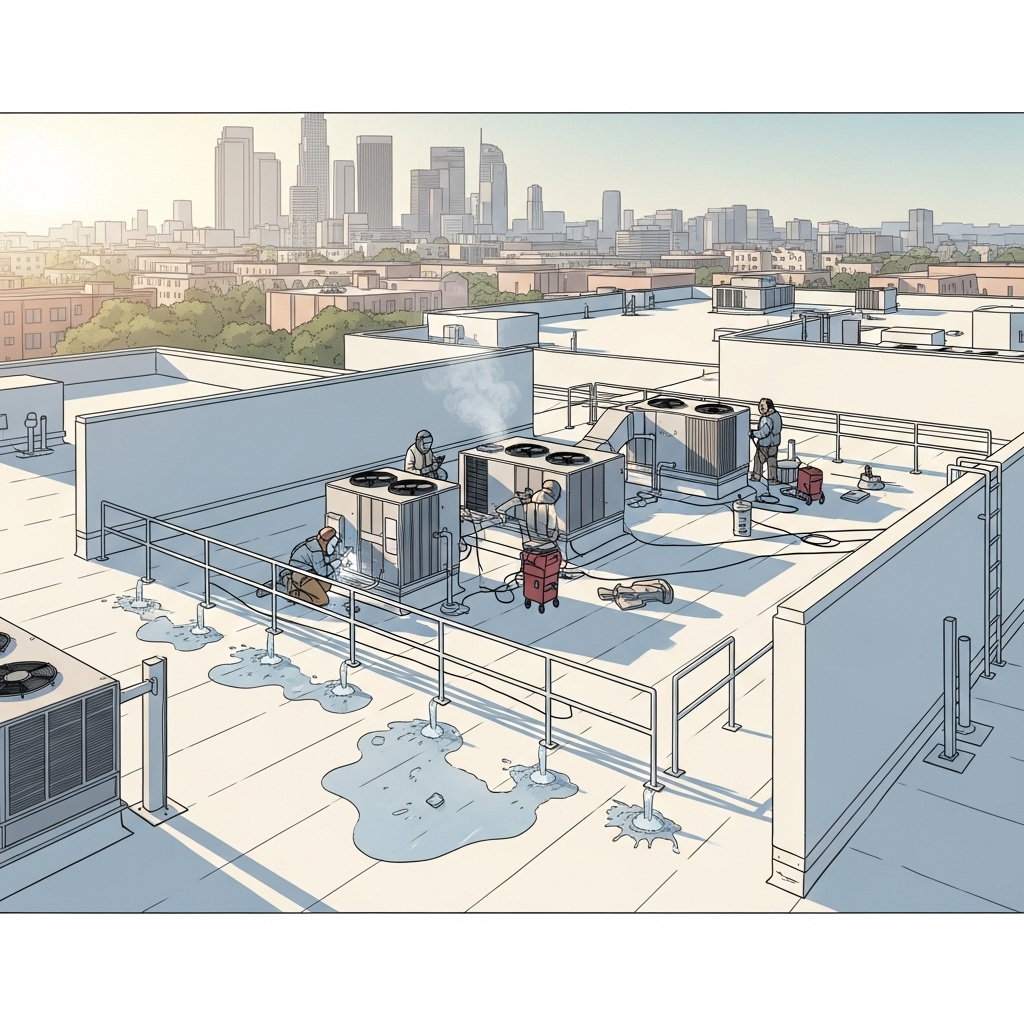

Commercial roofing is less about curb appeal and more about performance, access, and safety. A successful project accounts for the footprint of HVAC units, skylights, solar arrays, vents, and parapets that often crowd the field. The design also responds to Los Angeles’s energy requirements, particularly cool roof criteria that shape membrane choices and surface characteristics. The best solutions resolve details around drains, scuppers, and expansion joints, and provide a durable platform for ongoing maintenance of rooftop equipment.

Understanding the Building’s Mission

The first step is clarifying how the building serves its occupants. Warehouses prioritize watertightness and durability under foot traffic for maintenance crews. Retail locations add concerns about customer experience during construction, including noise and parking. Office tenants care about consistent indoor comfort and minimal disruption to operations. For mixed-use properties, the roof may shield both commercial and residential zones, requiring careful sequencing and communication to respect quiet hours and access rules.

Commercial roofs often span large areas, which means thermal movement, drainage, and slope become essential design elements. Even small ponding areas can stress membranes over time. Experienced Los Angeles contractors understand how to introduce tapered insulation to encourage drainage without creating problematic transitions at parapets and equipment curbs. The goal is a surface that sheds water predictably and preserves the warranty terms of the chosen system.

Membrane Systems Common in Los Angeles

On low-slope commercial roofs, single-ply membranes such as TPO and PVC are common choices, appreciated for their reflectivity and welded seams. Modified bitumen remains a dependable option, especially where robust puncture resistance and multi-ply redundancy are valued. Built-up roofing still appears on legacy buildings and can be adapted or replaced depending on condition and performance goals. Coatings can rejuvenate certain assemblies, but when a replacement is warranted, the emphasis shifts to a clean substrate, reliable terminations, and detailing that anticipates thermal movement and service traffic.

Each system has its own attachment methods—mechanically fastened, fully adhered, or ballasted—and those methods interact with wind exposure, deck type, and code requirements. In LA’s varied microclimates, UV protection and heat tolerance remain central considerations. Parapet height, curb details, and edge metal profiles all work together to keep wind uplift in check while maintaining a crisp, professional appearance from the street below.

Title 24, Cool Roofs, and Energy Strategy

California’s energy standards strongly influence commercial roof design, and in Los Angeles, cool roofing is often a given for low-slope surfaces. High-reflectance membranes reduce heat gain, easing HVAC loads and improving comfort for top-floor tenants. Compliance is not just about paperwork; it’s also about a roof assembly that integrates insulation levels, air and vapor control as necessary, and details that prevent thermal bridging at edges and penetrations. An energy-informed roof is part of a larger building strategy that supports stable indoor conditions and long-term operational efficiency.

Many property owners use the replacement opportunity to reassess rooftop equipment layouts. Relocating units for better service access, consolidating penetrations, or adding walk pads can reduce incidental damage over time. When combined with a reflective membrane and improved insulation, these changes help the assembly work as a quiet partner in the building’s daily life.

Access, Safety, and Occupied Buildings

Commercial projects in Los Angeles frequently unfold over active businesses. Safety plans are tailored to the layout—stairwells, hoists, and controlled access points keep materials moving while protecting employees and customers. Fall protection, fire safety, and daily housekeeping are non-negotiable, and thorough communication with on-site management ensures the schedule respects peak hours and critical operations. On multi-tenant properties, signage and emailed updates help occupants anticipate when certain areas will be noisier or temporarily rerouted.

Urban sites introduce their own choreography. Loading zones may need to be reserved, cranes scheduled for off-peak hours, and debris removed with minimal impact on neighboring storefronts. Seasoned Los Angeles crews know how to maintain professionalism and a clean site even on tight blocks where every inch counts.

Coordination With Other Trades

Commercial roofs host an ecosystem of equipment and penetrations. Coordinating with HVAC contractors, electricians, and solar providers is as important as choosing the membrane itself. Curbs and sleepers must be flashed to the manufacturer’s standards to preserve warranties, and penetrations should be grouped where possible to minimize future risk. Clear documentation and as-built drawings help building engineers track what’s installed so maintenance teams can work confidently without compromising the assembly.

Skylights and smoke hatches also deserve attention. Older units may not meet current performance expectations, and replacing them during the roofing phase can bring daylighting and code compliance up to current standards. It’s the ideal time to standardize sizes, confirm proper curbs, and ensure terminations are watertight and durable.

Mid-Project Reviews and Quality Control

A disciplined commercial job includes checkpoints to verify adherence to specifications. Pull tests, seam probes, and photo documentation of substrate conditions give owners assurance that the assembly meets both manufacturer requirements and code. Midway through, many teams hold a review meeting to confirm progress, highlight any discoveries from tear-off, and recalibrate sequencing as needed to keep business operations running smoothly. At this stage, it helps to revisit the overarching goal of the roof replacement: a reliable, maintainable surface that supports the building’s mission for the long term.

Drains and scuppers receive particular scrutiny because they are high-consequence details. Ensuring correct sump formation, strainer installation, and compatible metals sets the stage for years of trouble-free performance. Walk pads around equipment reduce wear in service routes, and edge metal installed to tested standards keeps the system secure against wind uplift.

Documentation, Warranty, and Closeout

Commercial replacements conclude with a packet of submittals, warranty registrations, and maintenance guidelines. Manufacturers often require specific details and inspections before issuing final coverage. This documentation is more than a formality; it’s a roadmap for caring for the roof over its service life. Owners and facility managers should keep digital and hard copies accessible so future staff can reference them quickly.

Closeout meetings also establish expectations for maintenance and access protocols. A roof that performs for decades is one that gets routine inspections, debris removal, and timely attention to small issues before they grow. Establishing a maintenance cadence at turnover helps protect both the building and the investment you’ve made in the new assembly.

Special Considerations for LA Properties

Some Los Angeles buildings sit in high fire severity zones or adjacent to open space. In those cases, ember resistance and Class A assemblies are essential. Others sit near the coast, where salt air pushes the team toward stainless or coated metals and equipment that tolerates corrosion. Downtown sites may contend with tight schedules and neighboring construction, demanding close coordination to share access routes and loading areas. These local realities are part of why a commercial roofer with deep LA experience adds measurable value from the first site walk.

Finally, seismic awareness threads through commercial work here. While roofs are not typically structural in the seismic sense, coordinating with engineers about rooftop equipment anchorage and movement paths ensures the assembly accommodates motion without tearing membranes or overstressing flashings. It’s one more way experience translates into resilience.

Frequently Asked Questions

How long does a commercial roof replacement take in Los Angeles?

Timelines depend on building size, membrane choice, and access. Projects often proceed in phases to keep businesses operating, with daily goals set to minimize disruption. Weather, inspections, and coordination with other trades also shape the schedule.

Can work continue while tenants occupy the building?

Yes. With a clear safety plan, controlled access, and good communication, crews can replace roofs over active spaces. Managers are kept informed about noisier activities and temporary routing so operations remain as normal as possible.

What systems are common on commercial roofs here?

Single-ply TPO and PVC, modified bitumen, and occasionally built-up roofing are common. The right choice depends on the building’s needs, energy goals, and service traffic. Reflective surfaces are often favored to meet energy standards and improve comfort.

How do cool roof requirements affect decisions?

Cool roof criteria guide surface reflectance and sometimes color, especially on low-slope assemblies. They support lower heat gain and can help stabilize indoor temperatures. Your contractor will present compliant options that work with your building’s layout and equipment.

What kind of maintenance should follow a commercial replacement?

Regular inspections, especially after wind or rain events, and routine clearing of drains and debris protect the membrane. Walk pads near equipment, careful service protocols, and timely repairs keep the roof performing and preserve warranty coverage.

Is coordination with HVAC and solar providers necessary?

Absolutely. Penetrations, curbs, and mounts must be flashed to system standards to protect warranties. Coordinating schedules and documenting the final layout helps maintenance teams work safely without compromising the roof.

Partner With a Los Angeles Commercial Roofing Team

If you’re planning improvements for your property, a conversation with a local specialist can align the project with your operational calendar and energy goals. Reach out to discuss your building’s roof replacement and map a sequence that keeps tenants comfortable, protects equipment, and delivers a clean, maintainable assembly for years to come.